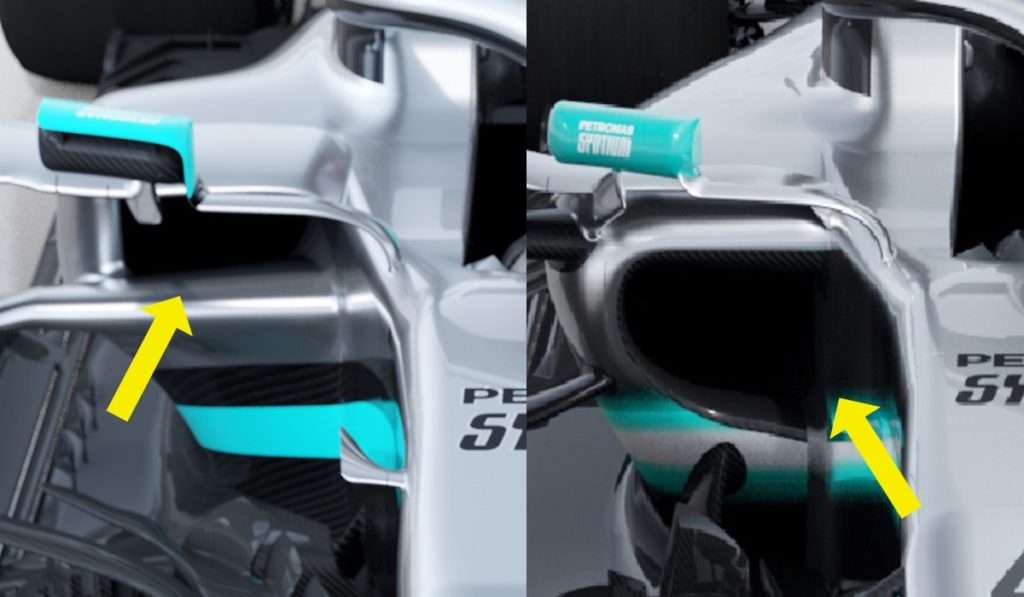

Looking at the Mercedes W11 next to the 2019 championship-winning W10 and the most striking visual difference, besides the flashes of red from new sponsor INEOS, is the huge difference in the size of the sidepod inlets (below).

This change to a much smaller inlet on the W11 may come as a surprise, given Mercedes struggled with its cooling last season. Many would expect a larger opening to channel more air through the radiators to cool the engine fluids, but Mercedes have gone in totally the opposite direction.

This makes sense from a performance angle as larger openings equals more drag, which is something no team wants, therefore Mercedes have had to make some major internal changes to accommodate this smaller inlet.

The team’s technical chief, James Allison, explained that a rearrangement of the radiators has allowed them to create a larger surface area, so the cool air that enters the car is working more efficiently at cooling the engine – something the team couldn’t change mid-season.

“We’ve improved the cooling package,” said Allison. “We’ve created more face area – so more actual radiator area in the car – which is a difficult thing to do mid-season without incurring quite a lot of penalty.

“But between the years you can do it and it won’t cost you except a little bit of weight.”

The sidepods are also far slimmer (below) at the rear thanks to the relocation of its side impact protection structure. By lowering the uppermost spars and bringing them forward, it has allowed them to better package the radiators and power unit allowing for a more extreme undercut.

“In the middle of the car we have followed the pitlane trend by moving our upper side impact tube to the lower position and banking the aerodynamic gain that comes with this layout.”

[twenty20 img1=”28534″ img2=”28535″ offset=”0.5″ before=”W10 (2019)” after=”W11 (2020)” hover=”true”]

The engine has also undergone some advancements in cooling to allow it to operate at a higher working temperature without compromising performance.

Allison added: “We’ve also benefitted from an investment that HPP (Mercedes’ engine division)) have made on our behalf. They’ve worked to raise the operating temperature of the engine which eases the cooling burden on us because the hotter the fluid, the less radiator you need to cool it.”

HPP chief Andy Cowell admitted it’s been a difficult task to achieve, but says it’s vital the engine division finds solutions to make the aerodynamicists job a little easier.

“We are putting significant effort into making sure that all the cooling fluids on the Power Unit operate at a higher temperature,” added Cowell. “This increases the temperature difference between that coolant fluid and the ambient temperature that we are racing in, which increases the effectiveness of the cooling system.

“That’s a tough challenge though, because large parts of the engine are made from aluminium and the temperatures that we are operating at mean the material properties are decaying quite rapidly. Managing that over an eight-race distance Power Unit cycle is a tough engineering challenge but that’s what we are striving for.

“As Power Unit engineers we don’t just focus on crankshaft power, we also focus a tremendous amount on the packaging and reducing the overheads for the aerodynamicist, so that they can mainly focus on keeping the car planted through the corner.”

Discussion about this post